Facility + Quality

TAM’s facility has maintained ISO 9001 certification since 1992 and we take great pride in our continued efforts to maintain and improve consistency throughout every product line. Our system of total quality management involves every employee in customer-centric methods of process improvement. We are aware of the value that our customers place on quality and will continue to utilize all available methods to maintain and enhance our standing as an industry leader.

Chemical and physical analysis are performed on each TAM lot in our spectrographic or metallurgical laboratories. This ensures top product quality and compliance with customer specifications. Tests are conducted within ASTM standards using some of the most modern equipment available and a detailed certificate of analyses accompanies each lot that is shipped. To support our quality-conscious workforce and provide superior products, our laboratories utilize state of the art analysis techniques such as:

Philips WD-XRF (Wavelength Dispersive X-Ray Florescence)

Philips XRD (X-ray Diffraction)

ICP (Simultaneous Inductively Coupled Plasma Spectrophotometer)

Perkin Elmer AA (Atomic Absorption Spectrophotometer)

Leco Carbon/Sulfur analysis

Microtrac and Coulter Laser Particle Sizers

Micromeritic Sedigraph

Quantachrome Nova BET and Monosorb Surface Area

Density Determination via UltraPyc gas pycnometer

Viscosity, PH, and Conductivity testing

Sieve Analysis through 500 mesh

Bulk and Tap Density Testing

We have systematic process controls in place including FMEAs used to assess and manage risk, MSA & Gage R&R studies used to define instrument capability, and SPA (NWA) used to define and monitor process capability. Our employees are also dedicated to safety, and as of December 2010, TAM has gone over 6 years without a lost-time work injury.

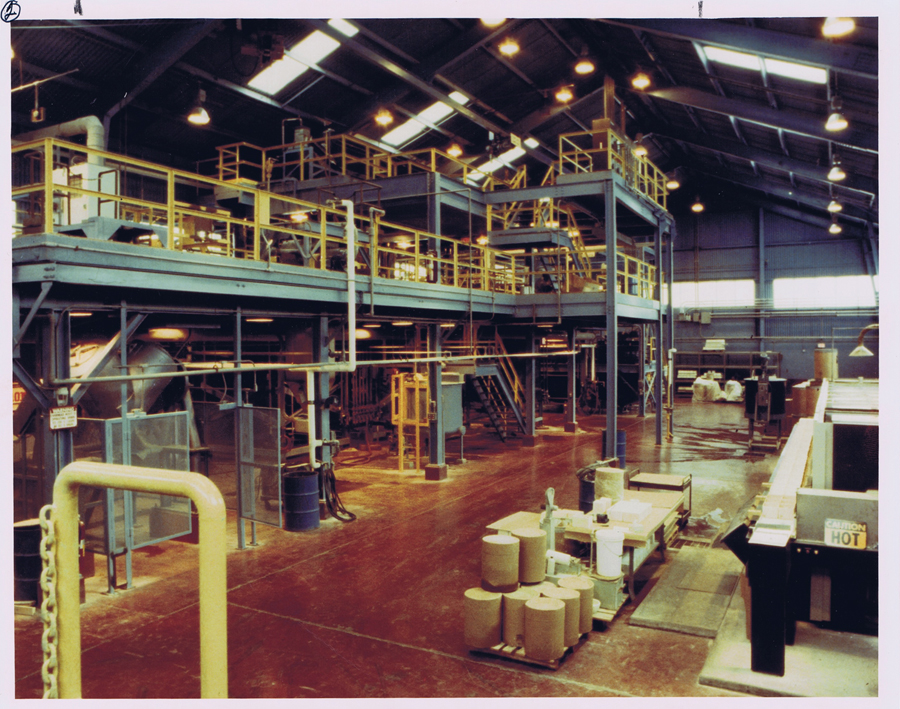

TAM’s Niagara Falls site features 374,000 square feet under roof, set on 34 acres of land. The plant runs on renewable hydroelectric power. In addition to low-cost power, our competitive advantage comes from access to our diverse assets, including, but not limited to:

Heat treatment

Large firebrick lined direct-fired rotary calciners

2 large Harper rotary calciners

Harrop and Harper pusher kilns

Pilot scale firings

Milling Capacity

Ball Mills loaded with various sized, composition grinding media

M-80 Sweco Mills

Large capacity Pulverizers

Jet Mills 16-24″

Drying Capacity

Drum dryer

Belt dryers

4 Large Quincy tray dryers

Impact dryer

Chemical plant

Solids neutralization plant

50 large stainless tanks

25 small tanks

Acid resistant tanks

Blending

Large ribbon blender

Large cone blender

Several Vee blenders

Plant / facilities

Boiler and Chiller systems

High volume Air System

Electrical infrastructure

Offices and Testing labs

If you are in need of laboratory support for application development or research products or toll testing, please contact our engineering department. We believe in partnering with our customers to provide detailed characterization of materials. If you have a challenging application or are in need of third-party testing, we will work with you to resolve your technical issues.